Entries • 2) Algae Production Systems

CLICK ON IMAGE or Registration Number to see larger version of exhibit.

1112. Bill Rucks, Water Alchemy Ltd.

1112. Bill Rucks, Water Alchemy Ltd.

Goal: Grow Outstanding Algae Live Photo-Bioreactor.

Self-cleaning domestic photo-bioreactor, simple to operate, cost effective, and will fit on a kitchen countertop. Built to last with few moving parts. High quality, quiet and energy efficient. Can switch species and grow AFA, chlorella and spirulina.

2113. Video. Min Thein, Myanmar Pharmaceutical Factory.

2113. Video. Min Thein, Myanmar Pharmaceutical Factory.

Algae Production System of Natural Spirulina Lakes in Myanmar.

Based on 22 years of lake harvest experience, sustainable spirulina production from natural lakes has been achieved in Myanmar. By 2000 capacity reached 200 tons per year, producing one million bottles of nutritional supplements, as well as crackers, cosmetics and beer.

2114. Video. Spirulina Ladies of Chad, by Georges Bonnin.

2114. Video. Spirulina Ladies of Chad, by Georges Bonnin.

Kanembou Spirulina Ladies of Chad.

We are a group of 1581 women harvesting spirulina from the wild in wadis in the Kanem and Lake regions. Producing nearly 400 tons/year, we are one of the world’s largest producers. Our product retails on the local market at the average price of 7.5 euros/kg, the world’s cheapest.

2117. Akos Kovacs.

2117. Akos Kovacs.

Algae Production System for Sustainable Transport Depot in London.

Reinventing a multi-story car park in Marylebone near Baker Street Station as a training, holding and support facility for sustainable urban transport. Photobioreactor cells arrayed over the facade of the building would provide biofuel for cars and contribute to environmental control.

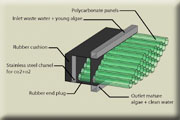

1118. Roy Mahoff and Stefan Schlau.

1118. Roy Mahoff and Stefan Schlau.

UREF: Universal Renewable Energy Farm.

UREF is an outdoor clear, very strong polycarbonate (PC) honeycomb photobioreactor (PBR) tailored to growing micro-organisms such as algae regardless of climate and geography. The UREF optimizes full light for high productivity and minimizes photo inhibition and photo saturation.

2118. Vincent Guigon, Antenna Technologies, Geneva.

2118. Vincent Guigon, Antenna Technologies, Geneva.

Circular Tank Technology to reduce production costs.

Antenna is an NGO promoting spirulina against malnutrition with projects in Africa and Asia, with a mission to make spirulina more affordable. Circular tank technology decreases costs by 20% through long lasting maintenance of culture quality, without purges, and free water stirring.

2120. Video. University of Illinois at Urbana Champaign.

2120. Video. University of Illinois at Urbana Champaign.

AlgaeWheel-based Algae Cultivation for Environmental Enhancing Energy. This novel approach integrates algal wastewater treatment with hydrothermal liquefaction of biomass to biocrude oil, resolving two bottlenecks: contamination of target high-oil algae species with low-oil algae and bacteria, and high energy input for dewatering algal biomass.

2121. Video. Laurent Lecesve, Hybrid énergies & Eco-Systèmes.

2121. Video. Laurent Lecesve, Hybrid énergies & Eco-Systèmes.

Organic spirulina microfarm with biogas plant. Normandy, France.

The farm contains 4 ponds of 50m2, micro-digester, heat pump with heat network connected to digester and ponds, harvesting room with press and solar dryer, and a culture laboratory. The goal of the digester is to grow spirulina organically using cow and horse manure as main inputs.

2122. Asbjorn Torfason, Visvaen Orka, Iceland.

2122. Asbjorn Torfason, Visvaen Orka, Iceland.

LED Based Photobioreactor.

A low cost energy efficient LED (Light Emitting Diode) photobioreactor (PBR) system suitable for biofixation of carbon dioxide (CO2) by microalgae. The patent pending PBR system is scalable, easy to install and can use either sunlight or artificial LED lighting for 24hr operation.

2123. John L. Cowan III.

2123. John L. Cowan III.

Tri‐Helix Solar Powered Algae Bioreactor.

To produce algal efficiently it is necessary to limit energy input. Gravity and a pulley system fill the bioreactor and harvest. A solar powered aerator provides aeration for mixing. The pulley system allows out of solution gases to escape vertically due to a change in angle of tubing.

2124. Stephen Lyon.

2124. Stephen Lyon.

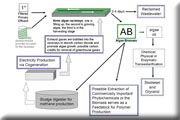

Design of an Algae-Based Wastewater Treatment Process.

Flow diagram of an algae-based wastewater treatment system with multiple benefits. Revenue analysis is needed for wastewater treatment, sale of phytochemicals, energy produced from cogeneration from leftover biomass and revenue from synthetic polymer production.

2125. Video. blablabLAB: R. Nieves, G. Rubio, T. Saxena & M. Caminal.

2125. Video. blablabLAB: R. Nieves, G. Rubio, T. Saxena & M. Caminal.

Haberlandt bio-reactor kitchen. Fresh algae vending machine.

This biotechnological vending machine grows and maintains algae in a super optimized, continuous production state. It is designed for any culture, currently spirulina. By spherificating the dose, it avoids any packaging. Haberlandt produces, stores and delivers in the same place.

2126. Video. Mahamat Sorto, Food Technology Consultant, FAO-Chad.

2126. Video. Mahamat Sorto, Food Technology Consultant, FAO-Chad.

Improved technology, production and marketing of dihé in Chad.

Goals were improving harvest, good manufacturing practice and commercialization of dihé (spirulina) and living conditions of communities around Lake Chad. The income of women has increased dramatically. Project funded by the European Union and implemented by FAO.

2128. Josh Wolf.

2128. Josh Wolf.

Algae Production System using night cycle LED.

A combination of blue, red, and green lighting during the algae’s night cycle will increase growth rate. This innovative system has artificial and natural lighting working together, a new way to look at LED lighting, solar powered, recycled algae drying method, night and day aeration.

2129. Video. Jiamjit Boonsom.

2129. Video. Jiamjit Boonsom.

Boonsom Spirulina Farm. Thailand’s Leading Producer of Spirulina.

For 20 years, our farm offers the rural community an opportunity for a better life. Keys are sunlight, clean water, environment and the work force. Our farm is not dependent on high tech equipment. We employ hundreds of people in research, cultivation, harvesting, production.

2130. Video. Algaetech, Malaysia.

2130. Video. Algaetech, Malaysia.

Algae Integrated Management System (AIMSYStm).

AIMSYS is a method for designing an algae cultivation system for biofuel, food, feed, and high value products. The major highlight of this design is the web based system monitoring and control of all the parameters such as pH, salinity, nutrient concentration and dissolved oxygen.

1112. Bill Rucks, Water Alchemy Ltd.

1112. Bill Rucks, Water Alchemy Ltd.

Viper: Vehicle Photo-Bioreactor.

This vehicle mounted photo-bioreactor will go on any mobile vehicle. Potential end users are taxi companies, government fleets, buses and vehicle manufacturers. Simple design, no moving parts, scalable and adaptable with components typically locally available.

SF Bay Area Spirulina Microfarm

SF Bay Area Spirulina Microfarm